AFT Brings Flooring Installation Training Cross Country

My Floors Flooring America in Galion, Ohio, hosted an Advanced Flooring Technology course. Photo: AFT.

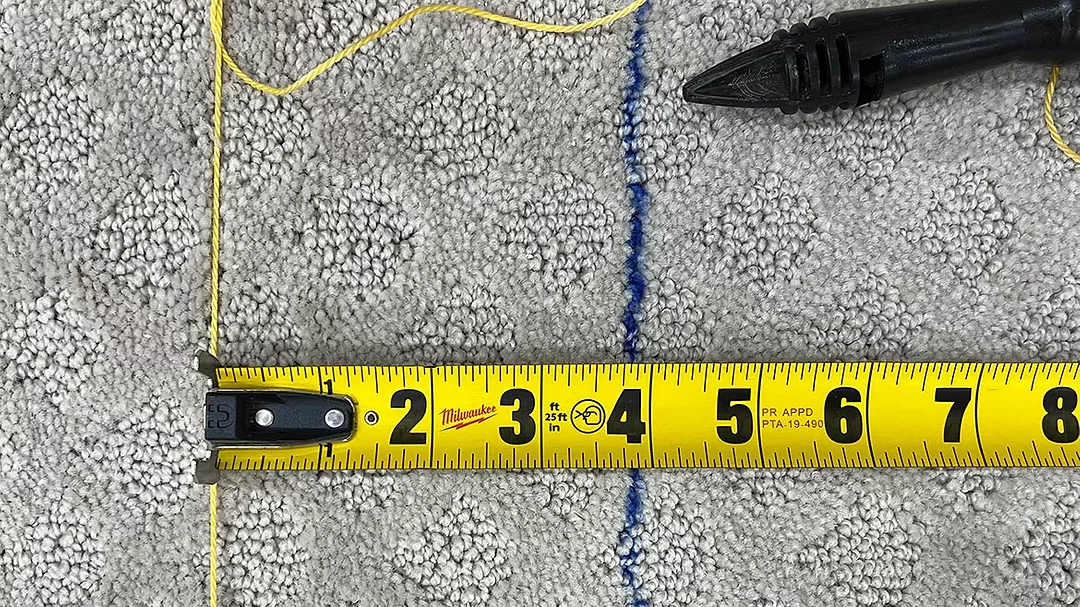

In the One-Day Custom Seam Class, students will learn how to identify the construction of all soft surface materials and how to create a better seam. Photo: AFT.

Students get hands-on training in the carpet seaming course. Photo: AFT.

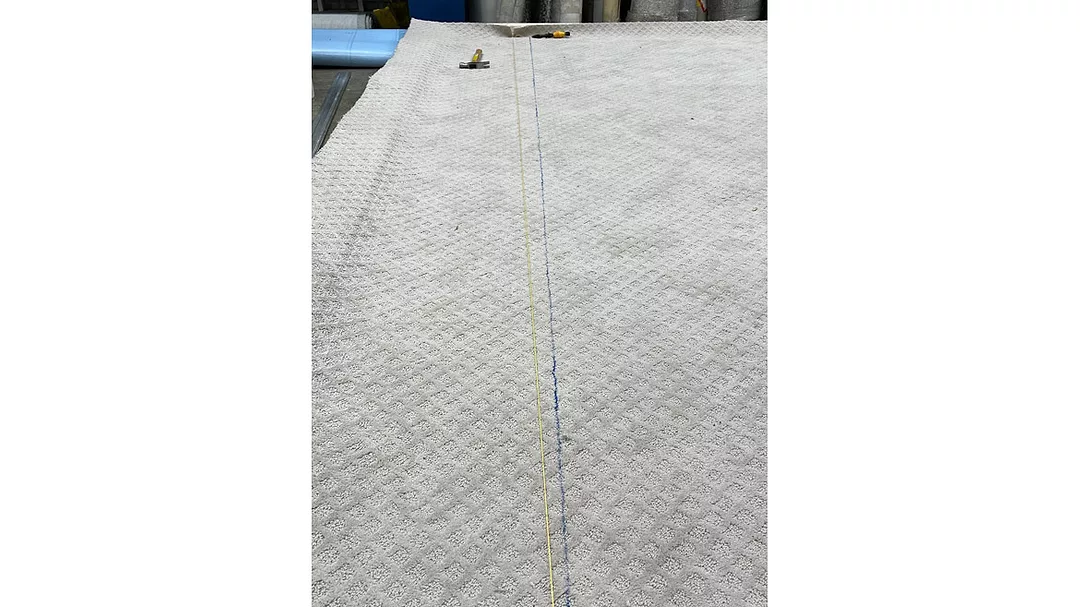

Students get the opportunity to experience real-world issues with patterned carpet. Photo: AFT.

The Two-Day Pattern Correction Class teaches how to properly identify and how to correct pattern bow, skew and elongation. Photo: AFT.

Students stretch in carpet during hands-on carpet courses. Photo: AFT.

Students participating in carpet correction course. Photo: AFT.

Robert Varden works with a student during carpet seaming course. Photo: AFT.

A job well done! Photo: AFT.

Advanced Flooring Technology (AFT) is quickly gaining momentum as an installation training and certifying body for the floorcovering industry, working with organizations like the International Union of Painters and Allied Trades (IUPAT) and CCA Global. It was recently approved for scholarship funding through the Floor Covering Education Foundation (FCEF). The company was founded in 1988 by Robert Varden, and according to Varden, AFT was built on four pillars: installation, education, training and research.

AFT offers six different training and certification options that can be found on its recently launched website. The LVP Class is a one-day, hands-on session where participants will install both glue-direct and floating LVP. In the One-Day Custom Seam Class, students will learn how to identify the construction of all soft surface materials and how to create a better seam. The Two-Day Pattern Correction Class teaches how to properly identify and how to correct pattern bow, skew and elongation. The Six-Week Classroom/On-the-Job Class for Carpet & LVP (luxury vinyl plank) is a three-phase course designed to take a beginner helper to a proficient assistant installer. The Residential Resilient Class and Commercial Resilient Class focus on all aspects of resilient installation.

Varden said after surveying the training programs he designed and has been involved with over the years, he found that many took too long. For example, International Floorcovering Installers (CFI) offers a five-week course that teaches students how to start in installation.

“The CFI program is phenomenal, but what I'm getting from a lot of dealers is it is so hard to send a kid off for five weeks,” Varden said. “We did a lot of research, talked to a lot of retailers, and the magic number seemed to be about two weeks.”

For example, AFT’s Six-Week Classroom/On-the-Job Class for Carpet & LVP training, announced this year, uses a three-phase approach. The course combines the two-week classroom training with a minimum of four weeks of hands-on and on-the-job training. This allows students to move from the classroom directly into using what they just learned, solidifying the education. Additionally, the four weeks hands-on portion can be extended to any length of time needed. The student can return to complete the next phase of the training as time allows.

Varden emphasizes the difference between training and certification: training covers the basics through hands-on demonstration, while certification evaluates an installers’ skills.

“Anybody who goes through a certification will learn a lot, but the goal there is to evaluate that individual’s skills and see if they earn a particular level of whatever that certification is,” he added.

Retailers and distributors who would like to host training for installers in their region are invited to contact AFT who will design a program based on its six training programs that fit specific needs.

“We’ll also give you a checklist to help you set up your facility for a training session, tools and materials you’ll need, and what to expect,” Varden said.

In the six-week course, participation is limited to six to eight students and can be performed in-house anywhere in the U.S.

“I've got two dealers right now they're looking at doing it in-house, and they have no problem putting together six students to make it happen,” Varden said. “They'll do it in two-week increments there at their own facility.”

For more information on the certification and training courses, click here.

See coverage of AFT’s seaming class through CCA Global here.

For more AFT news, click here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!