How to Perform a Mat Bond Test Prior to Resilient Flooring Installation

Congoleum’s AirStep Evolution was used to demonstrate how to properly perform a bond test prior to installation.

Photo: John Steier.

Commercial contractors perform bond tests regularly—or at least they should be! But what about residential contractors? Performing a mat bond test prior to the installation of resilient floor covering is a great way to ensure that you are using the correct adhesive with the correct product and that both will adhere to each other and to the subfloor. Performing a mat bond test helps identify the appropriate open and working time for the site conditions and any potential issues prior to installation.

In many cases, residential resilient installations require more preparation ahead of time. How often do you have to remove existing materials prior to installation? Is the subfloor contaminated with old paint or glue? How often is the subfloor you are working with flat and level? How often do you discover that you are installing over a subfloor that can’t accommodate glue-down flooring? Do you need to perform a moisture test? Moisture is a common issue under resilient installations and can prevent the adhesive from bonding properly. All of this should be considered before completing a mat bond test.

Locating the mat bond test steps for each product can be tricky; however, some commercial flooring manufacturers include them in their installation instructions. For example, Nora’s Installation Instructions have a “Mat Bond Test” section that explains why the test is important, what you are looking for and the steps required to perform the test. Forbo’s “Adhesive Mat Bond Testing” section is found in its Substrate Evaluation & Preparation Guidelines and not in the installation instructions. Additionally, Forbo’s guidelines list the most common failures and provide an explanation for each.

If there are no specific bond test instructions available for the flooring you are installing, refer to ASTM F3311-19—The Standard Practice for Mat Bond Evaluation of Performance and Compatibility for Resilient Flooring System Components Prior to Installation.

ASTM F3311-19 1.1 This practice is designed to provide a short-term qualitative evaluation of the effectiveness and compatibility of the composite layers for flexible and fully adhered resilient flooring installation(s). Aspects of the resilient flooring assembly to be evaluated may include concrete surface profile (CSP), surface preparation, a topical moisture mitigation system, underlayment product(s), primer(s), application and the installation of the resilient flooring material itself. Aspects such as surface profile, surface cleanliness, surface porosity, the application method(s), and the open, curing, and drying times of each layer of the flooring system can be assessed using this practice prior to the actual full-scale installation taking place.

It's important to know that every bond test for each product will vary. Some will require a two-foot square area while others require a three-foot area. Some will recommend waiting 24 hours and others 48. What’s most important is that you follow the installation instructions for the product you are putting down. After all, this is a mockup installation, so you must use the exact techniques and tools required for the full installation.

This bond test was performed in a controlled environment where the flooring and adhesive were acclimated 48 hours prior to testing. No mold or mildew was present. The subfloor was cleaned prior to the porosity test; however, the porosity test along with visual inspection indicated that the subfloor needed further preparation.

To test for porosity, place a quarter-sized amount of water on the surface and allow to sit for five minutes to see if it absorbs. The water remained standing on the concrete after the five-minute mark.

The concrete appears to either have a sealer or some kind of contamination as well as lots of pitting. Mechanical preparation of the concrete needs to be done prior to the resilient mat bond test.

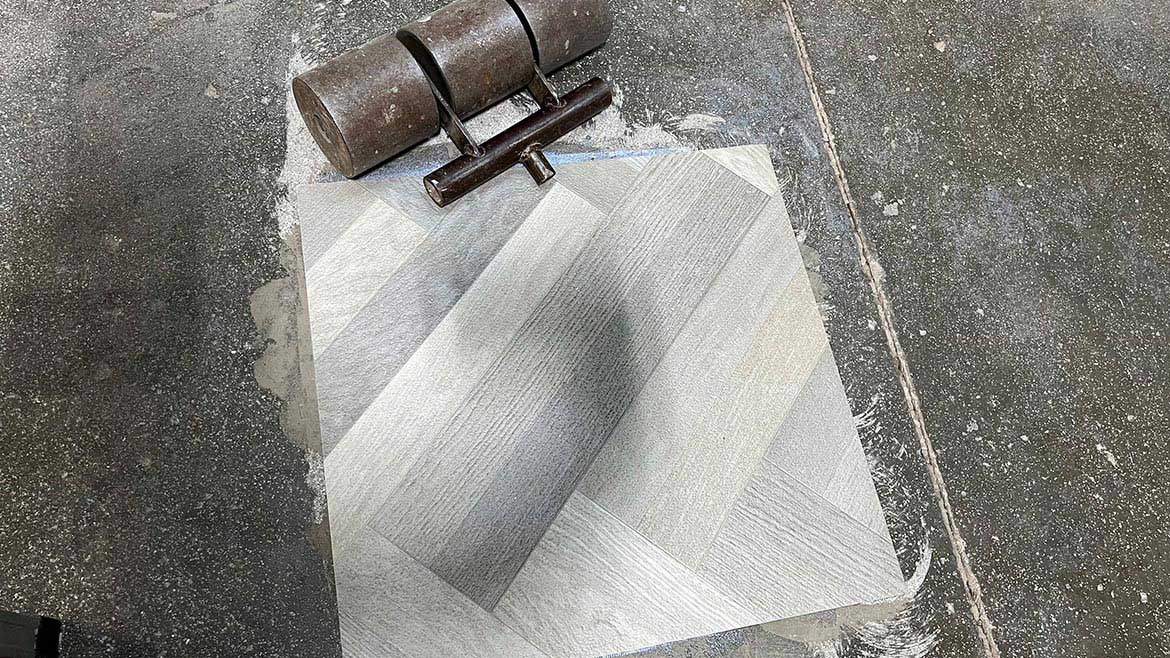

Mechanically remove any sealer or contamination on the concrete in two-foot square area.

Ardex Feather Finish is used to smooth out concrete after grinding.

Spread Congoleum’s CR021 Adhesive with proper notched trowel. Congoleum’s AirStep Evolution recommends 1/16” x 1/32” x 1/32” U-notched trowel.

Back roll the adhesive using a nap roller.

Install material according to directions and wait 24 hours. Check material 24 hours later to make sure the material stays in place and has adhered successfully.

Pull back wearlayer material to show that backing has successfully bonded.

Ideally, you would complete the bond test ahead of installation to allow time to correct or determine other options if the bond test fails and to perform another test. It’s important to note that the test is only able to yield results for the environmental conditions at the time of testing. If you perform a test several weeks ahead of installation, and for example, the HVAC gets turned on just prior to installation (it should already be on), the conditions have just changed. The test is no longer valid. Time to test again! So, consider adding mat bond testing to your menu of flooring installation services and save yourself and your client time and money.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?t=1690771780)