Ongoing Shift to Non-PVC Flooring Prompts Healthcare Installers to Seek Booster Shot of Specialized Training

As healthcare facilities shift to non-PVC luxury vinyl flooring, installers need specialized training on new adhesive techniques that fundamentally change project execution.

As healthcare facilities shift to non-PVC luxury vinyl flooring, installers need specialized training on new adhesive techniques that fundamentally change project execution.

As healthcare facilities shift to non-PVC luxury vinyl flooring, installers need specialized training on new adhesive techniques that fundamentally change project execution.

As the healthcare industry intensifies its focus on safer, healthier, and more sustainable building materials, architects and designers are increasingly specifying non-PVC luxury vinyl tile (LVT), plank, and sheet goods. These products are visually similar to their traditional counterparts, but for installers, the shift to non-PVC versions is far more than cosmetic. To properly install these products, flooring professionals must employ alternative adhesive specifications and application techniques that are often overlooked and more time-sensitive. The installation differences also impact the broader flooring process, making accurate bidding, scheduling, and coordination with other trades more complex.

To help healthcare flooring installers understand this shift, here is a look at PVC versus non-PVC flooring, how the installation processes differ, and the training that teaches proper techniques.

Growing Concerns Over PVC-containing Products

Traditional PVC-containing flooring materials, such as vinyl composition tile (VCT), standard sheet vinyl, and LVT, were a long-time choice for their affordability, durability, and easy maintenance. More recently, however, the health and environmental implications of PVC have prompted healthcare stakeholders to seek safer, more sustainable alternatives. Key concerns driving the shift to non-PVC alternatives include:

- Chemical exposure. PVC flooring can contain phthalates (plasticizers used to increase flexibility) and other additives that can off-gas volatile organic compounds (VOCs) into indoor environments. These emissions can contribute to respiratory irritation, asthma, and long-term health effects, particularly in sensitive populations in a healthcare setting.

- Maintenance burden. Products like VCT require frequent stripping, waxing, and polishing, which involves regular use of harsh cleaning chemicals and adds to facility operational costs. These processes expose maintenance staff to potentially harmful substances and contribute to indoor pollution.

- Green building conflicts. PVC-based materials often conflict with the goals of sustainable design. Institutions seeking Leadership in Energy and Environmental Design (LEED) certification are incentivized to avoid materials with known environmental hazards. Similarly, the WELL Building Standard discourages the use of materials that release harmful emissions or pose toxic exposure risks.

- Disposal and environmental risks. PVC flooring is notoriously difficult to recycle due to its complex composite structure and chemical additives. When burned in incinerators or deposited in landfills, it can pose risks to air and water quality.

Triggered by these health, environmental, and maintenance concerns, the healthcare industry has accelerated its move away from PVC flooring toward safer, more sustainable alternatives.

Why Non-PVC Products Have Gained Favor

Non-PVC products, in the forms of plank, tile, and sheet goods, address many of the health and environmental issues posed by PVC by removing the problematic material from the equation. Specifically, non-PVC products are recognized for providing:

- Lower VOCs. New non-PVC flooring products are typically low in VOCs, making them a safer choice for healthcare environments and patients with respiratory conditions or weakened immune systems.

- Easier maintenance. Non-PVC flooring products used in healthcare typically have simpler, less labor-intensive maintenance requirements. Their durability and smooth surfaces allow them to be effectively cleaned with milder, environmentally friendly agents, reducing the need for harsh chemicals and significantly lowering overall maintenance costs.

- Alignment with green building initiatives. Many PVC-free products meet the criteria for green building certifications such as LEED and WELL, making them an attractive choice for healthcare facilities aiming to achieve environmental and regulatory goals.

- Reduced environmental impact. Because non-PVC flooring does not contain plasticizers or chlorine-based ingredients, it can significantly reduce the potential for toxic emissions throughout its lifecycle.

As a result of these advantages, non-PVC flooring products have emerged as a preferred choice for healthcare facilities committed to safer, more sustainable building practices.

3 Critical Reasons Non-PVC Training Is Recommended

For installers transitioning to non-PVC flooring, the shift is far more complex than simply swapping one product for another. Many PVC-free materials, such as LVT and plank, look similar on the surface, but their installation requirements are notably different from their predecessors—a key reason training is essential. The three most important features of non-PVC training are:

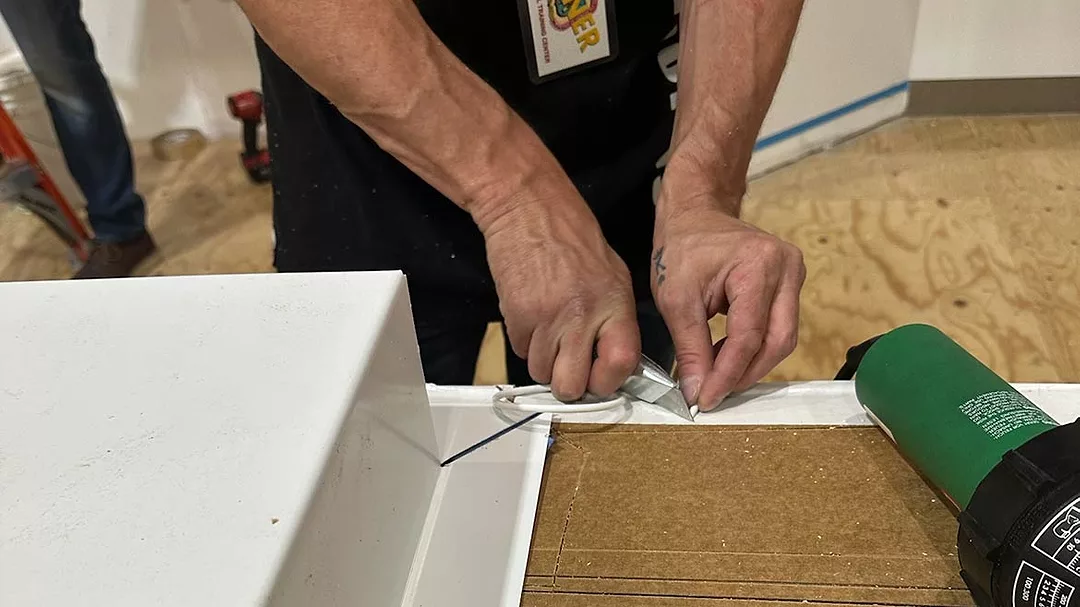

- Adhesive application. The non-PVC tile and plank products popular in healthcare applications often require a two-part urethane adhesive. The adhesive must be precisely mixed on-site using manufacturer-recommended equipment. During training, installers are instructed on correct mixing ratios, batch-size limitations, and blending techniques, as well as how to manage the adhesive’s short working time. Unlike standard pressure-sensitive adhesives, two-part urethanes require installers to work off the material, placing and rolling the flooring as they go due to the longer set time and irreversible curing chemistry.

- Lower dimensional stability. Non-PVC products tend to be less dimensionally stable, making them more sensitive to temperature changes, moisture, and humidity. These conditions affect how the flooring expands or contracts once in place. Installers must accurately anticipate these changes using up-to-date moisture testing methods and equipment, and they must adjust their layout, spacing, and acclimation procedures accordingly. If these factors are not properly accounted for, the flooring may gap, buckle, or fail to lie flat, compromising safety, aesthetics, and long-term durability.

- Impact on project timing. The longer adhesive set time directly impacts how a job is bid, planned, and managed for efficiency and productivity. Crews trained in non-PVC installations are much less likely to run the risk of delays, wasted materials, and flooring failure due to adhesive application error. Training instructs installers not to assume the same adhesive used on a previous project, or even a different product from the same manufacturer, will work for any other non-PVC material. The compatibility of these products is highly specific, and installers must follow the manufacturer’s exact installation guidelines to assure the flooring’s performance, protect the warranty, and prevent costly rework.

Overall, formal training demonstrates that the visual similarities between PVC and non-PVC flooring materials can be misleading and the technical requirements for PVC-free products can be more demanding. Installers need specific knowledge and experience to select and apply adhesives correctly, account for dimensional stability, and successfully manage projects from bidding through completion. Without training, even seasoned flooring professionals can encounter serious challenges that jeopardize project success.

Preparing for Future Complexities

Looking forward, the fundamental skills involved in healthcare flooring installations, such as cutting, fitting, and adhering, are unlikely to change. What will certainly change is the complexity of the landscape surrounding those basic skills. Installers will need to keep pace with all aspects of healthcare installations. That includes advances in product formulations as well as evolving substrates, moisture testing methods, adhesive formulations, and sustainability requirements. Ongoing professional development, specialized training, and hands-on practice will be imperative for navigating these complexities and ensuring success.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!