Why Did the Heat-Melt Fail?

Adhesive Not Dry: Manufacturers recommend a minimum amount of time between the installation and the start of heat welding, generally overnight (except when using a dry-to-the-touch adhesive at the seam). The reason? The high heat from the welder will cause any moisture in the adhesive to turn into moisture vapor that will stop the thermo-fusion process from thoroughly taking place. The time between the installation and welding is worth the wait.

Straight Edge and Butt: The straight edge and butted seam is used by a lot of installers. They use this method not realizing the seam edges are gapped in some areas and tight in others.

When the groove is cut in the seam where the edges of a seam are not evenly spaced or the groove is not centered on the seam, it will leave one side of the groove no radius at the base of the groove. The radius at the bottom of the groove is extremely important to the integrity of the seam weld. Without the groove at the weld base, there is undue stress to the seam edge and usually results in a failure of the weld.

Moving Too Fast: Installers weld at different rates of speed. They need to know and work at a speed consistent with their heat setting. Installers that change speeds will find the integrity of the weld will change along the seam, ranging from scorching to poor fusion.

Sudden Movement of the Welder: An installer will generally reach out and pull the heat welder toward his body; as he gets the welder close to his body, he will move. When he moves, it is necessary to maintain a constant fluid movement. Any sudden movement will cause a jump at the weld tip. This will generally leave about a two-inch loose spot in the weld failure. If this happens, the installer needs to remove that section and re-weld it. It is a simple process often overlooked.

Groove Cut Too Deep: The depth of the groove in sheet vinyl is specified by manufacturers to be 1/2-to-2/3 the thickness of either the wear surface on materials with a backing or the thickness of the material in vinyl-backed material. With vinyl products the installer must adhere to those specifications.

I have seen grooves cut completely through the material into and through the adhesive line into the substrate. Many installers confuse linoleum seams with vinyl seams; linoleum seams are grooved down to, but not into, the jute backing. If that is done with sheet vinyl, the seam will likely fail.

Groove Cut Too Wide: There are several diameters of weld rod available in the market place. If a groove is cut in the material too wide for the rod, the weld will be compromised. It is necessary for the installers to double-check the rod with the groover width prior to the start of the grooving.

Contamination of Groove: Some installers will tend to groove the entire area prior to the start of heat welding. This exposes the seam to contamination from dirt getting into the groove prior to the start of the heat welding, sweeping the grooves with a broom that has been contaminated with some type of sweeping compound, and construction traffic. Other situations occur when the seams are covered with tape. The residue of the adhesive on the tape will affect the material and/or the groove.

Poor Power Source: On a lot of commercial installations, power sources are a considerable distance from where the heat welding is taking place. When this is the case, it is necessary to have heavy-duty power cord the can handle the power necessary to run a heat weld gun.

The next thing to be aware of is the performance of the heat welder. If there is an insufficient amount of power or a weak power source, the heat-weld gun will surge. If the heat-weld gun is surging, seek an alternative source of power.

Poor Heat Setting: Allow the heat welder to thoroughly heat up. Some installers who are impatient will start to heat weld before the unit is totally warmed up. They get started, then find the temperature rising and scorching the material’s surface.

The heat welder needs to be set high enough to thoroughly melt the weld rod. Failure to do so will result in a poor fusion. The temperature setting is a small window between a good fusion and a poor fusion. Another factor is the temperature of the substrate. A cold substrate requires more heat; divining the correct setting requires experience on the part of the installer.

Crowding One Side of the Groove When Welding: Some installers tend to hold the heat welder on an angle, crowding one side of the seam. This will cause the seam to be weak along one side. The heat welder should be held straight up with a firm, but not hard, pressure on the weld tip. Too much downward pressure on the tip will tend to stretch the rod. When it cools, the weld rod wants to shrink and creates undo stress to the weld.

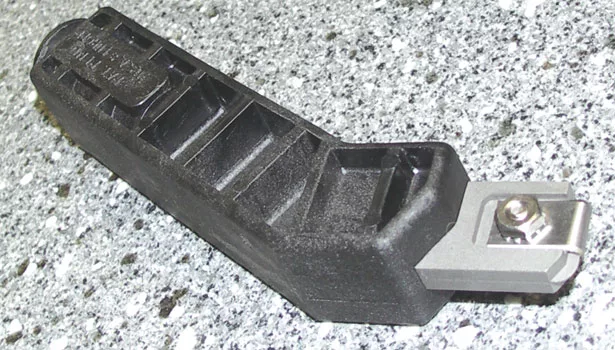

Improper Weld Tip or Use of the Tip: Weld tips should be designed for the rod and type of material being welded. The flow of the heat must be focused at the bottom of the groove as well as heating the rod. One of the worst problems with the hot air distribution is too much hot air wash, leading to scorching or distorting of the coating on the wear surface.

Skiving Too Early or Too Late: The skiving process needs to be done in two passes. Some installers try to eliminate the first pass to save time, but the end result is not worth cutting corners. The timing for the first skive is determined by the material being heat-welded: linoleum skiving should take place almost immediately while the weld rod is warm.

The same needs to happen with the second pass. Linoleum can be skived while the rod is warm. Linoleum is not a true weld; it is a thermo-bond, and waiting too long to make the final pass can jeopardize the bond of the rod.

On the other hand the skiving of the first pass in sheet vinyl seams need to be delayed until the material is cooled, normally 10-15 minutes. The final pass should be done when the seam is thoroughly cooled normally 20-30 minutes. Situations where the final skive has been rushed a seam in a vinyl product may be severely concaved. Heat-welded seams will have a minor concaving, but severe concaving will result in a maintenance issue.

Heat welding is an art when performed by an experienced professional. Installers that have perfected the art of heat welding pay strict attention to all of the job conditions and know how to compensate for the changes they will encounter. Few installers with minimal experience can go out to a job site and have a successful heat weld performance.

Heat welding requires a lot of experience; even experienced installers have difficulty, especially when heat-welding flash coving, inside and outside corners. A vinyl seam that is heat welded properly will be almost as strong as material without a seam.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!