Thin Tiles: Concerns and Expectations

There is not yet a clear understanding of how or where thin

tiles should be installed, especially in flooring applications.

Until recently, floor tiles have been 8 to 12mm thick and tiles less than 7.5mm were not intended for floors. However, tiles engineered to be thinner have now entered the marketplace. Made of porcelain, they are being marketed as “thin tiles.” Are they the same as their thicker brethren, except thinner? Being thinner they take fewer resources to manufacture and ship, but where and when can they be used?

Some thin tiles are formed using the traditional dust

pressing methodology – except they are thinner and have a lower breaking

strength.

What are thin tiles?

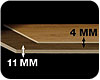

There are three categories of products being promoted as thin tiles. All three are 6mm or less, but there are important differences between them.In the first category, tiles are formed using the traditional dust pressing methodology. Such products are similar to traditional pressed porcelain tiles, except they are only 5 to 6mm thick and have a lower breaking strength.

In the second category, tiles are formed using a lamina process. Lamina tile products are produced in large, thin ceramic sheets, from which individual tiles can be cut. They are 3 to 4mm thick, are much lower in strength, and bend sufficiently to be installed on curved surfaces.

In the third category of thin tiles, lamina products are reinforced with backing materials. These backing materials are fiberglass or polymeric materials woven into a reinforcing mesh. Fused directly to the back of the lamina products with epoxy or other resin adhesives, the reinforced lamina tiles can be bent further and better resist breakage.

Strength concerns

All thin tiles, regardless of category, have a much lower breaking strength (less able to resist breakage when unsupported) than regular ceramic tiles. The ANSI A137.1 breaking strength requirement for floor tiles is 250-lbs. To date, no thin tile has met this requirement.Compared to regular tiles, thin tiles also behave differently when subjected to impact. Because they are thinner, they are less able to resist impact loading when unsupported. Even thin tiles with reinforced fiberglass backings have low impact resistance when unsupported, although sometimes the tiles puncture before they break.

In summary, thin tiles must be fully supported (i.e. installed with 100% coverage) to prevent damage from loading or impact.

Standard physical properties

To date there are no national consensus standards for thin tiles, and thin tiles fall outside the scope of existing tile specifications. With standardized values not yet set and differences existing between the three types of thin tile manufacturing, recommendations for suitability must come exclusively from the tile manufacturer.The ISO TC189 Committee for Ceramic Tile is creating an official Working Group to develop thin tile specifications. This group of experts is studying the unique physical properties of thin tiles, especially as they pertain to strength, and is determining how the different properties of thin tiles affect installations.

Large thin tile sheets made with lamina technology are

exceptionally thin, and their physical properties are very different from

regular tiles.

Adhesive concerns

As noted earlier, 100% thin-set or thick-bed coverage is critical for the successful use of thin tiles.Because thin tiles have a lower breaking strength, areas not supported by mortar will quickly fail, especially along the tile edges. Even in instances where full coverage is achieved, how rigid should the mortar be and how much mortar movement is acceptable? At present, these are unknowns.

There are also questions regarding which mortars bond the best to thin tiles. Thin tiles with fiberglass reinforcement likely require epoxy or reactive resin adhesives. Many thin tiles also come without a back pattern, and it has yet to be determined which mortars work best for those tiles. Mortar manufacturers are working to better understand the properties of thin tiles so they can develop installation recommendations and products specifically formulated for thin tile installations. However, it will be difficult to address such issues until a definitive standard for thin tiles is created.

Additional handling and installation challenges

The installation of thin tiles will be a new experience for many tile installers. Since large thin tiles can bend, they may follow simple substrate contours. While this can help reduce lippage, installations will appear different from traditional tile installations.Also, the installation of very large thin tiles, sometimes as large as 1m x 3m, can present unique challenges, especially when 100% coverage is necessary.

In summary

There are three general categories of thin tile products in the marketplace, all of which have a lower breaking strength than regular tiles. While standards development efforts are underway, there is not a national consensus standard for the physical properties of thin tiles at this time. Additionally, there is not yet a clear understanding of how or with which adhesives thin tiles should be installed, especially in flooring applications.Being thinner is an advantage when it comes to the costs of manufacturing and shipping, but until product standards, installation materials, and installation procedures are developed, the use of thin tiles for flooring applications should be approached with great caution.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!