Quick and Easy Movement Flooring Expansion Joints

Recently during a CTEF Educational Program, an installation manager for a large company complained that installing movement (expansion) joints in any application is a pain in the #?&. His complaint was that these joints never work, always require a callback to redo them and his installers refuse to use 100% silicone sealant.

Let’s look at this puzzle one piece at a time.

The issue of the movement joints not working occurred because the wrong product was being used. Lower-quality “caulking,” when used in tilework, can harden, shrink and many times fall out when there is movement in the structure. Due to its inability to remain flexible, an unsightly crack develops between the tile and the countertop or the tile and the bathtub. Now there is a callback from the builder (if the new house has not yet closed) or from the consumer. After listening to the complaint and writing down the details, someone needs to go to the site as soon as possible to fix the problem. The installer needs to rake out the “old” caulking, vacuum out the debris and install the new caulking.

Here is where the problem was occurring for the company mentioned above: the installer was sent to replace the caulking using the same product that failed the first time. That is Einstein’s definition of insanity—“doing the same thing over and over again and expecting different results.” If it failed the first time, it will probably do the same the next time.

The cure for this problem is to use the correct sealant, not caulking. The TCNA Handbook and the ANSI Specifications under section A108.01-3.7.4.1.1 state: “Suitable sealants include silicone, urethane and polysulfide.” You will notice this list does not include acrylic latex or siliconized latex caulking products.

Now the final issue: his installers refuse to use 100% silicone sealant. They refuse because they were never shown the correct method for installing silicones. There are two ways this may be done. The first is by installing foam backer rod into the joint; apply painter’s tape on the face of the tile along both sides of the joint, fill the joint with the silicone, smooth it with a sealant tool or a plastic spoon and remove the tape as soon as the joint is complete.

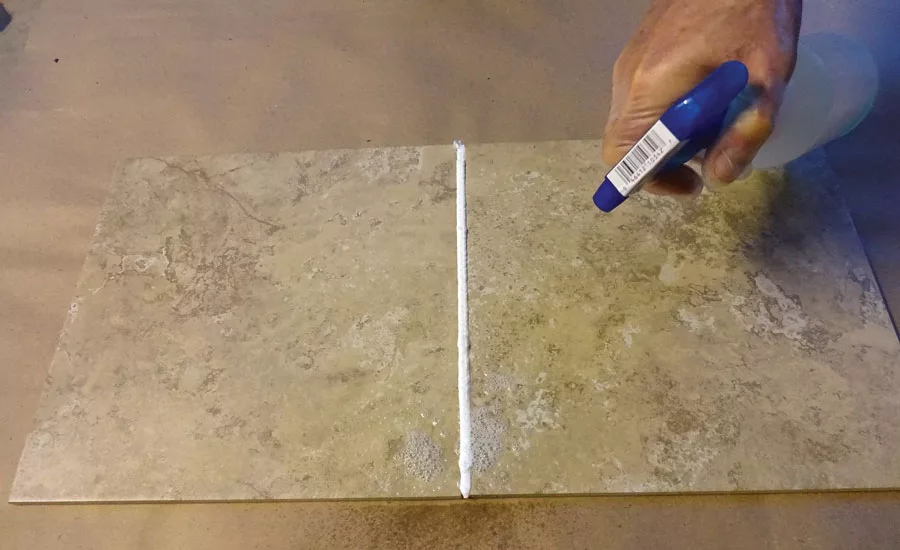

The second and easiest method involves filling the joint with the silicone sealant (no tape) then spraying the sealant and the face of the tile with a mixture of soapy water (Photo 1). The smoothing tool or plastic spoon can now easily remove the excess sealant without the worry of it sticking to the face of the tile as shown in Photo 2.

Sometimes something so simple can be a huge callback eliminator.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!