Tile Installation Instructions: The Answers are at Your Fingertips

Photo: Getty Images.

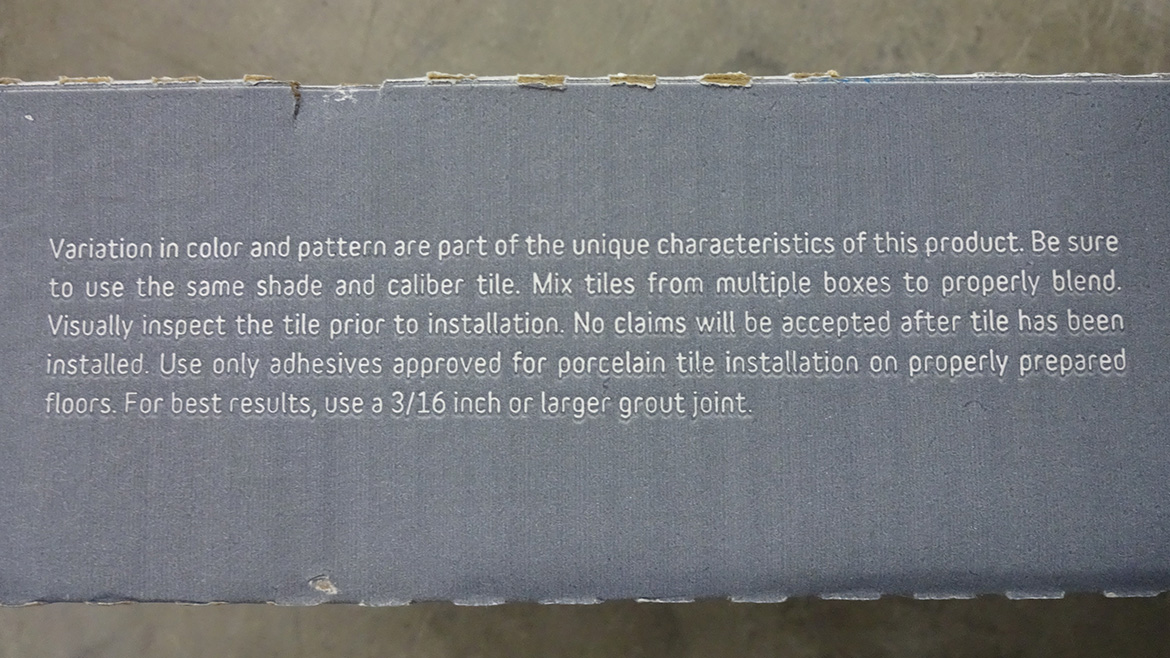

Sometimes the help that tile installers seek may be closer than they realize. Numerous tile manufacturers place installation tips and techniques on the cardboard box, many of which are based on the industry standards of the American National Standards Institute (ANSI) and industry recognized best practices. These instructions can be found on tile packaging: “Tile should be checked before laying. Claims cannot be accepted after installation. Mix tiles from different boxes and rotate them for a more natural and non-repetitive look.”

These statements provide a common-sense approach to eliminate tile shading issues. Blend tiles from four or five boxes to evenly distribute the shading for a pleasing look.

“Minimum recommended grout joint for this product is 1/8” (3/16” when installing tile with a length 15” or greater in a staggered brick-joint pattern); overlap (offset) should not exceed 33%. Not recommended – brick pattern 50% offset.”

Here is an example of a manufacturer's recommendation on the side of the box to assist the tile mechanic on installing the tile properly.

Photo: Scott Carothers.

ANSI A108.02-4.3.8.1 Running Bond/Brick Patterns

For running bond/brick joint patterns utilizing tiles (square or rectangular) with any side greater than 15 in., the grout joint shall be, on average, a minimum of 1/8 in. wide for rectified tiles and, on average, a minimum of 3/16 in. wide for calibrated (non-rectified) tiles.

ANSI A108.02-4.3.8.2 Running Bond/Brick Joint and Any Offset Pattern

For running bond/brick joint or any other offset patterns (i.e. non-continuous grout joints) utilizing tiles (square and/or rectangular) where the side being offset is greater than 15 in. (nominal size), only patterns with an offset of 33% or less shall be specified. If a pattern with an offset greater than 33% is desired, the specifier and owner must approve a mock-up and the resulting lippage.

“Be advised: prior to grouting the floor, please follow grout manufacturer’s recommendation and do a test patch to check for workability and cleanability of grout. Some heavily pigmented grouts represent cleaning concerns.”

The key advice here is to always test first. Never apply any grout to a tile surface without confirming that it will not leave a grout residue on the face of the tile. Applying a grout release on the tile face will aid in minimizing potential staining issues and make grout cleanup easier.

“ANSI A137.1 compliant. This tile complies with recommended standard specifications for ceramic tile ANSI A137.1”

The Ceramic Tile Education Foundation receives numerous questions about tile quality issues including warpage, sizing, squareness and shading. All these questions are addressed in the ANSI A137.1 American National Standard Specifications for Ceramic Tile document.

When these questions are received, our question to the caller is, “Was the tile tested to meet the A137.1 standard?” The answer most times is, “I don’t know.” If the tile has not been tested to meet these minimum requirements, the answer is “caveat emptor” which is the Latin phrase for “let the buyer beware” or what you see is what you get or maybe not. However, tile that meets the A137.1 requirements is normally easier and faster to install.

Additional ANSI Guidelines

A108.5

2.1.4 Wipe tile if dust is present from manufacturing or shipping.

2.1.5 Unless otherwise specified by the manufacturer, do not soak tile prior to installation.

2.2.1 Clean surface thoroughly. Dampen cementitious substrates if very dry, but do not saturate.

2.2.4 Installed tile should be removed periodically during the tile installation to check for specified mortar coverage requirements. (Dry areas at 80% and wet or exterior areas at 95%)

A108.02

4.4.1 Movement joints are required over all construction, control, and expansion joints in the backing and where backing materials change or change direction including terminations of tilework where it abuts restraining or dissimilar surfaces.

4.4.2 Movement joints are a requirement for tilework.

4.4.3 Movement joints shall be kept free and clear of all setting and grouting materials.

4.4.5 Install sealant after tilework and grout are dry. Follow sealant manufacturer’s recommendations.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!